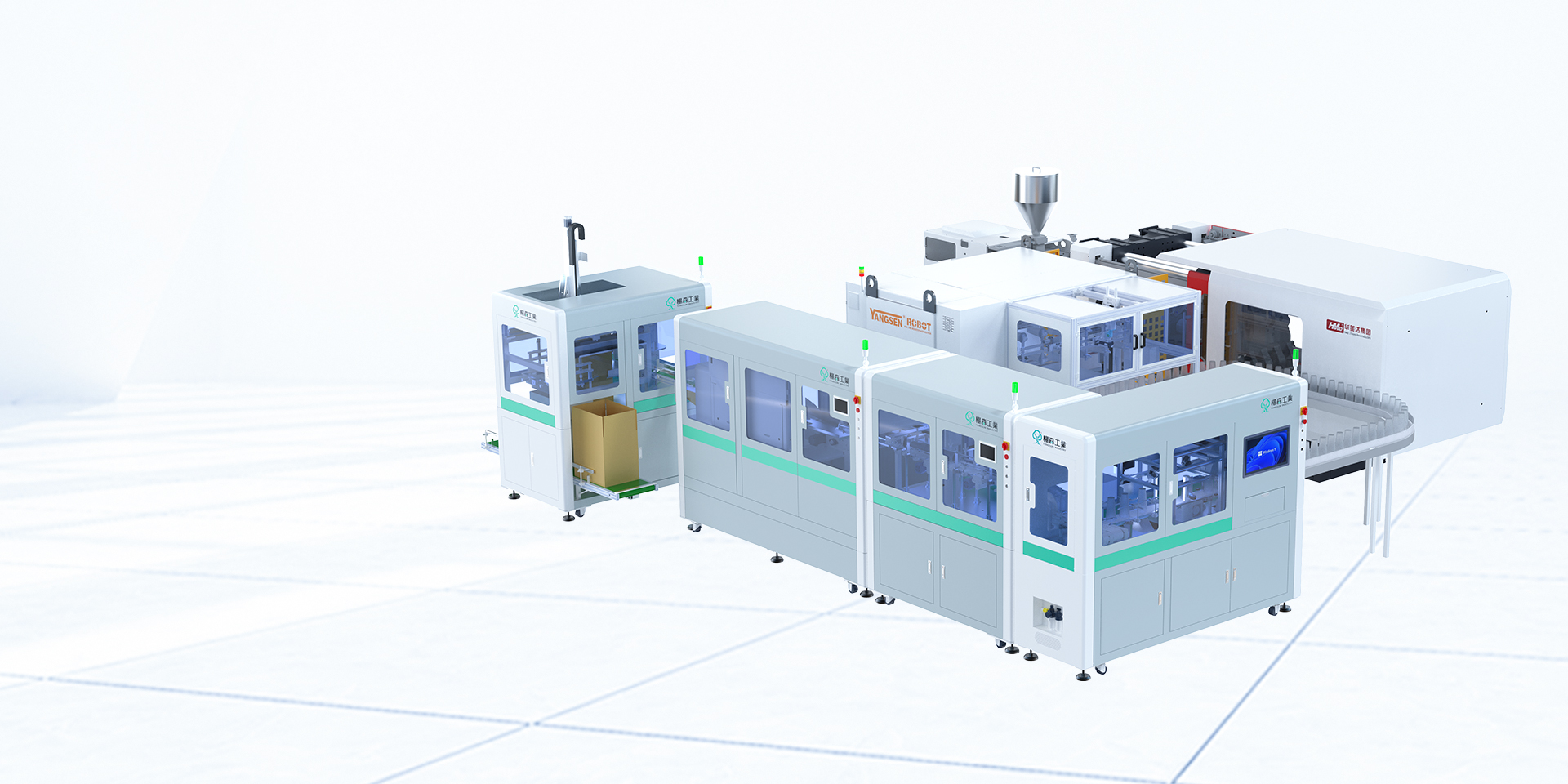

DIGITAL SMART FACTORY

SPECIALIZED IN INTELLIGENT MANUFACTURING

-

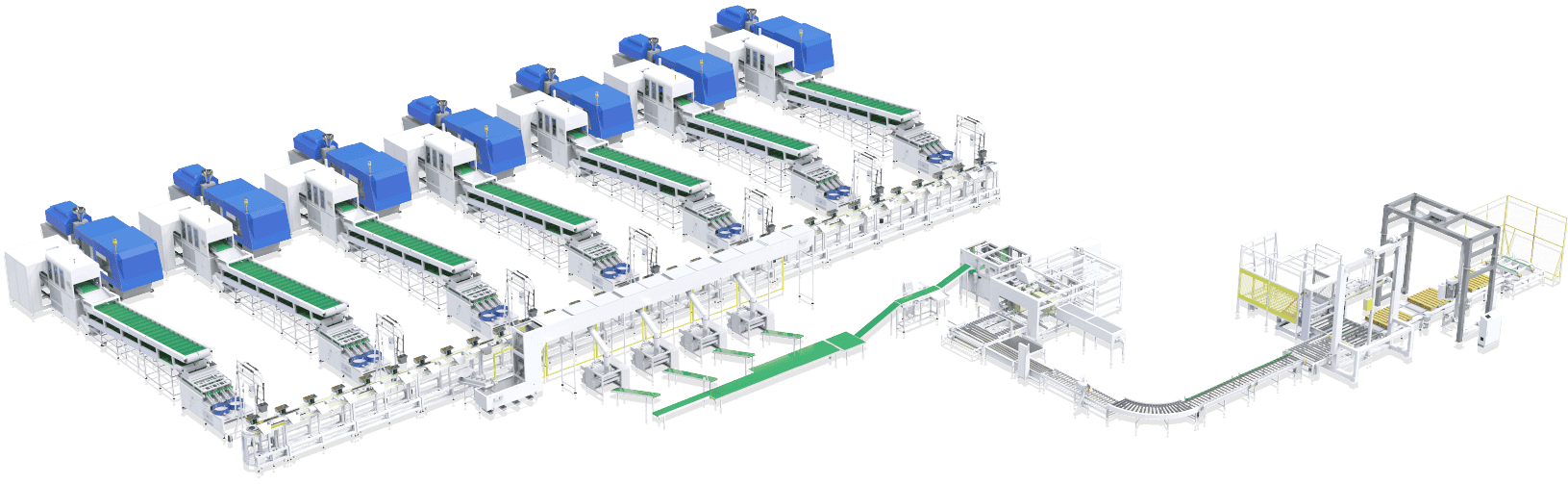

Smart Factory Solutions

Smart Factory Solutions

-

Food Container Packaging Solutions

Food Container Packaging Solutions

-

Preform pick-up Solution

Preform pick-up Solution

-

Packaging solutions for knives, forks and spoons

Packaging solutions for knives, forks and spoons

-

Powdered milk cap labelling solutions

Powdered milk cap labelling solutions

-

Product Visual Inspection Solutions

Product Visual Inspection Solutions

-

In-mold labeling solutions for bucket

In-mold labeling solutions for bucket

-

Injection Molding Machine Assembly Solutions

Injection Molding Machine Assembly Solutions

-

Porcelain Inspection Solutions

Porcelain Inspection Solutions

-

Magnetic Material Inspection Solutions

Magnetic Material Inspection Solutions

-

Chinese medicine Production Solutions

Chinese medicine Production Solutions

-

Injection Molding Removal Solutions

Injection Molding Removal Solutions

Proud attributes and capabilities

We combine proven methodologies with global best practices and quality assurance at every stage of the process to provide our customers with reliable and cost-effective turnkey repetitive equipment manufacturing services.

High-speed take-out

Self-developed high-speed algorithms to complete precise gripping and placing actions in a very short time, widely used in automotive manufacturing, electronics and electrical appliances, food and beverage, pharmaceuticals and chemicals, and many other industries....

In-mold labeling

Revolutionizing in-mold labeling technology with efficient and innovative labeling and pickup designs, broad label compatibility, and intelligent automatic stacking and conveying systems....

Workpiece sorting

Aaccording to the different colors, shapes or different quality requirements of the product, screening and sorting operations....

Product packaging

Automatic bagging, bagging, measuring, filling, vacuum (shaping), finished package output, to achieve unmanned packaging process....

Machine vision

With high efficiency, precision, flexibility and expandability, it can be customized and developed according to the specific needs of enterprises to better meet the needs of use....

Automatic cartoning

Using high-speed dispensing device, can pack various products, such as food containers, cups, irregularly shaped bags, etc., also suitable for packing boxes with dividers....

Intelligent palletizing

Integrates the functions of pneumatic gripping, pallet positioning, conveyor docking, safety protection, block software package and simple control system, etc., which can realize the intelligent palletizing of cartons, totes, bags and other multi-specification boxes....

Wrap-around packaging

Pallet wrap-around packaging of goods (e.g. for container transportation of large pieces of goods and packaging of bulk pallets, etc.), which can improve the efficiency of logistics and reduce the loss in the process of shipment....

Intelligent warehousing

Through automatic perception, automatic control, intelligent robots, intelligent information management, mobile computing, big data and other Internet of Things technologies, to improve the speed and accuracy of data input in all aspects of the goods warehouse, and to accelerate the speed of goods operation....

Achieve transparency of production data

Breaking data silos, integrating production, quality, equipment, energy consumption and other aspects of the data, to provide a comprehensive data source for visualization, better use of visualization data to guide production decision-making, to achieve improved production efficiency, optimization of resource allocation and product quality.

Learn more

Global Services

We build on our experience and innovation to grow organically, expand into new markets and realize new opportunities by providing superior solutions and services to our customers.